Production capacity and processes

Production Processes

We have the necessary resources to carry out the entire manufacturing process of bent parts and assemblies.

Our work is based on experience, precision, and technical consulting to provide tailored solutions at every stage of the process for the various sectors we serve..

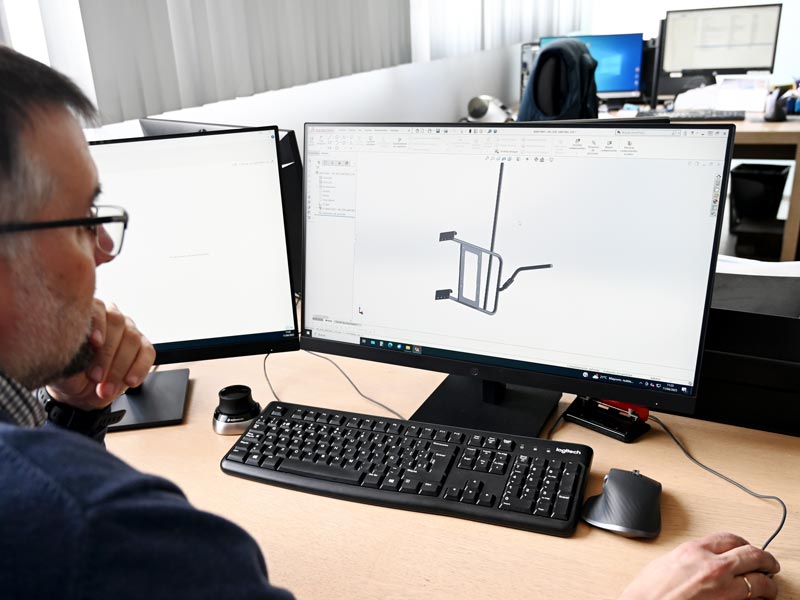

Technical office

We advise and analyze each project to define the best solution, optimizing both the design and the bending process.

Bending

We perform material bending using various technologies, adapting to the specific geometries of each project..

Finishing

We offer a wide range of finishes tailored to each type of material and requirement, enhancing the strength, durability, and appearance of the components..

Cutting

We prepare the material for cutting on automated machinery, ensuring precision, cleanliness, and optimal material utilization.

Welding

We perform welding of our products using MIG/MAG, TIG, and laser welding processes, ensuring precision, quality control, and compliance with manufacturing standards.

Production Capabilities

We have modern, specialized production resources that enable us to carry out bending, welding, and finishing processes.

Our infrastructure combines high-tech machinery, automated systems, and tools adapted to different types of materials and geometries, ensuring high-quality results in all our operations.

Tube bending capacity

-

- Capacity up to Ø 90 mm.

- Useful length up to 6,000 mm.

- Fixed radius, variable radius and interpolations.

- 3D process simulation software.

- CNC programming.

Additional equipment

-

- Automatic cutting line up to Ø 120 mm.

- TIG & MIG/MAG welding.

- Polishing and grinding machinery.

- Dust extraction booth.

Contact

© Magafor · Legal Notice · Privacy Policy · Cookies